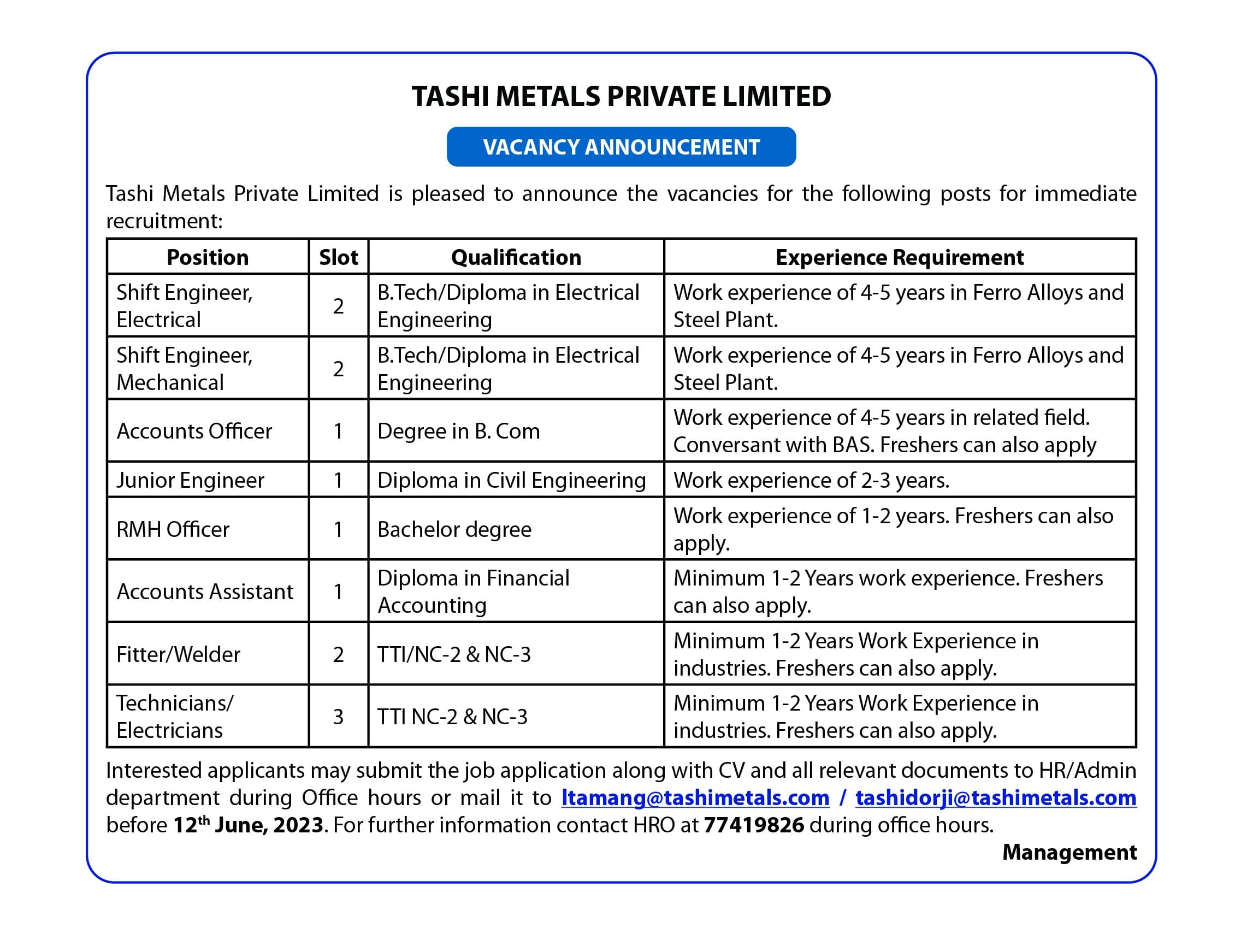

Autoclaved Aerated Concrete (AAC) Brick users in the country have increased overtime.

The concrete block company started supplying in the Bhutanese market since January, this year.

Based in Pasakha, Phuentsholing, Bhutan Ecolite Brix Private Limited (BEBPL) started manufacturing AAC blocks and launched the product this January. It is an FDI and has two Bhutanese shareholders and four Nepal-based shareholders.

Currently, the product is being used across the country for most construction purposes. The company’s Managing Director, Basant Nahata, said that the demand for the product has increased and the company could not meet the demand initially. The company was started with installed capacity of 50,000 cubic meters annually. Initially, the production was 18% per month. The company gradually increased the production to meet its installed capacity. So far, the company has supplied Nu 25mn worth of bricks in the market so far.

Being a time-tested product, he said that Bhutanese have started analyzing the product which has multiple advantages including economic and environment. It is 20% cheaper than the currently available red bricks from India. With increasing demand, the customers had to wait for weeks for product delivery. “But now, with the increased production we are able to meet their demand,” he said.

Despite the energy-intensive autoclaving process, manufacturers say it takes about 50% less energy to make, because of the lower portland cement content by volume. It’s lighter, which cuts down on transportation costs and fuel use. Each customer has taken more than 10 truckloads of bricks so far. “We have been receiving repeated orders, which means our customers are satisfied, have accepted and are confident about the blocks,” Basant Nahata said.

The bricks also have better advantage for the Bhutanese considering its geographical location, according to the Managing Director. The blocks being lighter than the red bricks are very suitable for constructions at steep gradients. The bricks prevent air leakage. Also, AAC blocks have excellent soundproofing properties. It can also be used as firebreak.

As 5% of Bhutan’s Gross Domestic Product is being spent on the import of red bricks in the country, the company feels that producing AAC blocks using the raw materials from industrial waste from within the country has helped in import substitution and meeting domestic demand for the construction materials.

The red bricks are imported from India.The best quality red bricks cost around Nu 12 per piece. The AAC blocks were in use in the country since five years ago. Earlier, they were imported from Guwahati in Assam and Siliguri in West Bengal, India.

The company plans to expand once its installed capacity is met. The plant currently produces around six truckloads daily. “We did not expect this much demand so early,” he said.

The company employs 40 expat workers at the plant and seven staffs in the office.

A customer in Thimphu said that the using AAC bricks are comparatively cheaper and faster. He is however yet to test the product. “There are multiple advantages as I am told and it is commonly used. During construction, it is easier. Now, I have to assess how it will be after completion,” he said. He is however using red bricks in his kitchen and bathrooms.

Krishna Ghalley from Phuentsholing