As part of their assignments, the teams have developed a solar powered vehicle, solar powered water heating system, and paver blocks from plastic waste

The undergraduate students of civil and electrical departments of the College of Science and Technology (CST) at Rinchending in Phuentsholing have come up with three projects, which are new in the country and themed on sustainability.

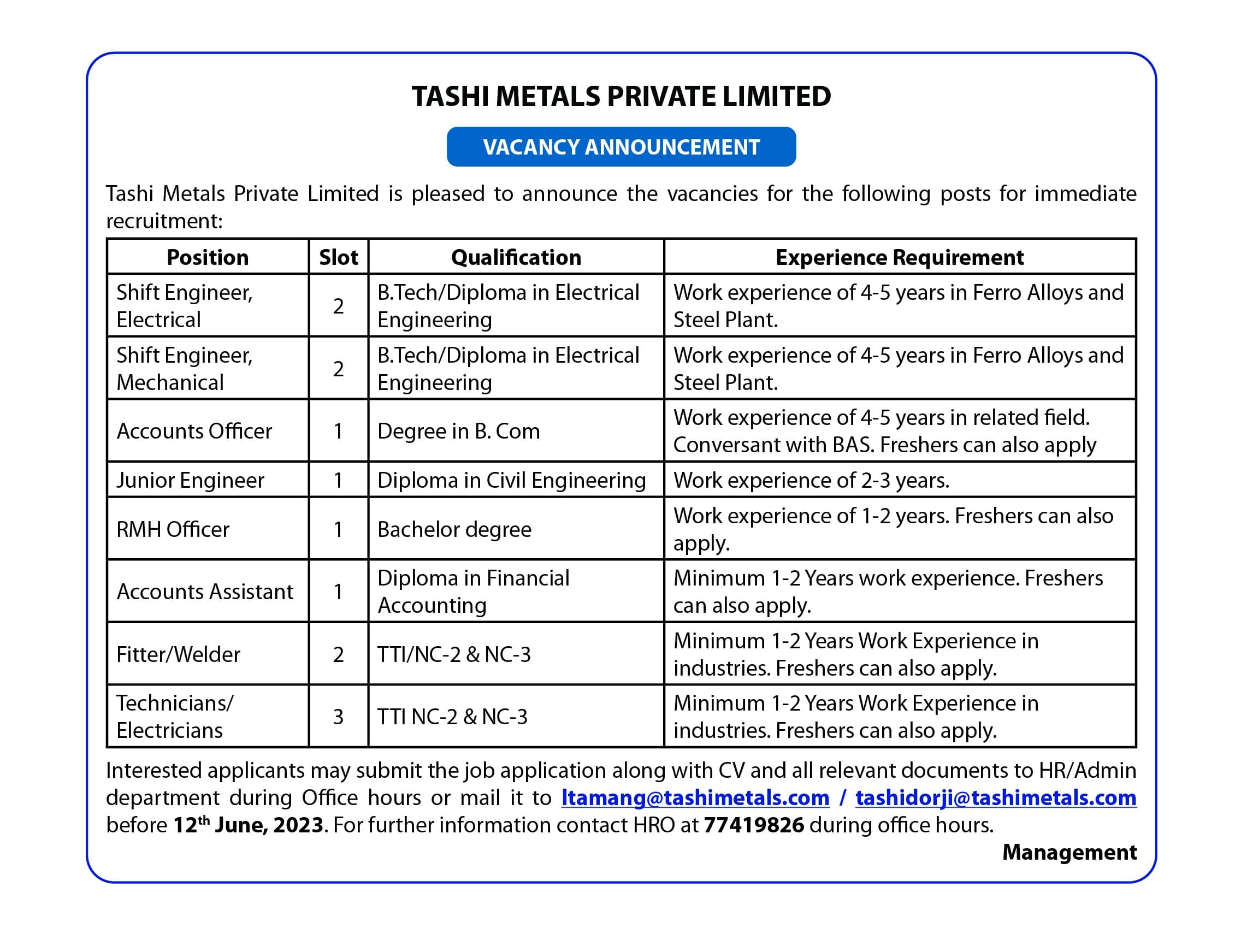

Low power drive solar electric vehicle

A team of three final year students has developed a solar powered three-wheeler car, which is now almost complete.

The team is striving to develop sufficient technological knowledge and experience in electro mobility and has also ventured into research and development of Electric Vehicle (EV) technology.

Accordingly, the team has developed a prototype model of EV where the solar panel is fixed at the vehicle roof to charge the car’s battery. The 320kg vehicle is waiting for solar panel to be installed soon. It took around two months to develop the vehicle and was completed by February end.

Meanwhile, the vehicle is also a part of project for the team during their ‘On Job Training’ from December in Phuentsholing.

As the county plans to introduce EV in the transport sector, the Centre for Renewable and Sustainable Energy Development (CRSED) under CST is developing sufficient technological knowledge and experience in the field of electro mobility.

A single motor configuration with the rating of 1,000watt is used in the rear axles of the vehicle to drive the load. The prototype vehicle has a battery bank capacity of 3.36kWh and a range of 16km could be achieved. These low power drive EVs can be used in the airports, high-end resorts, hotels, hospitals and sports stadiums.

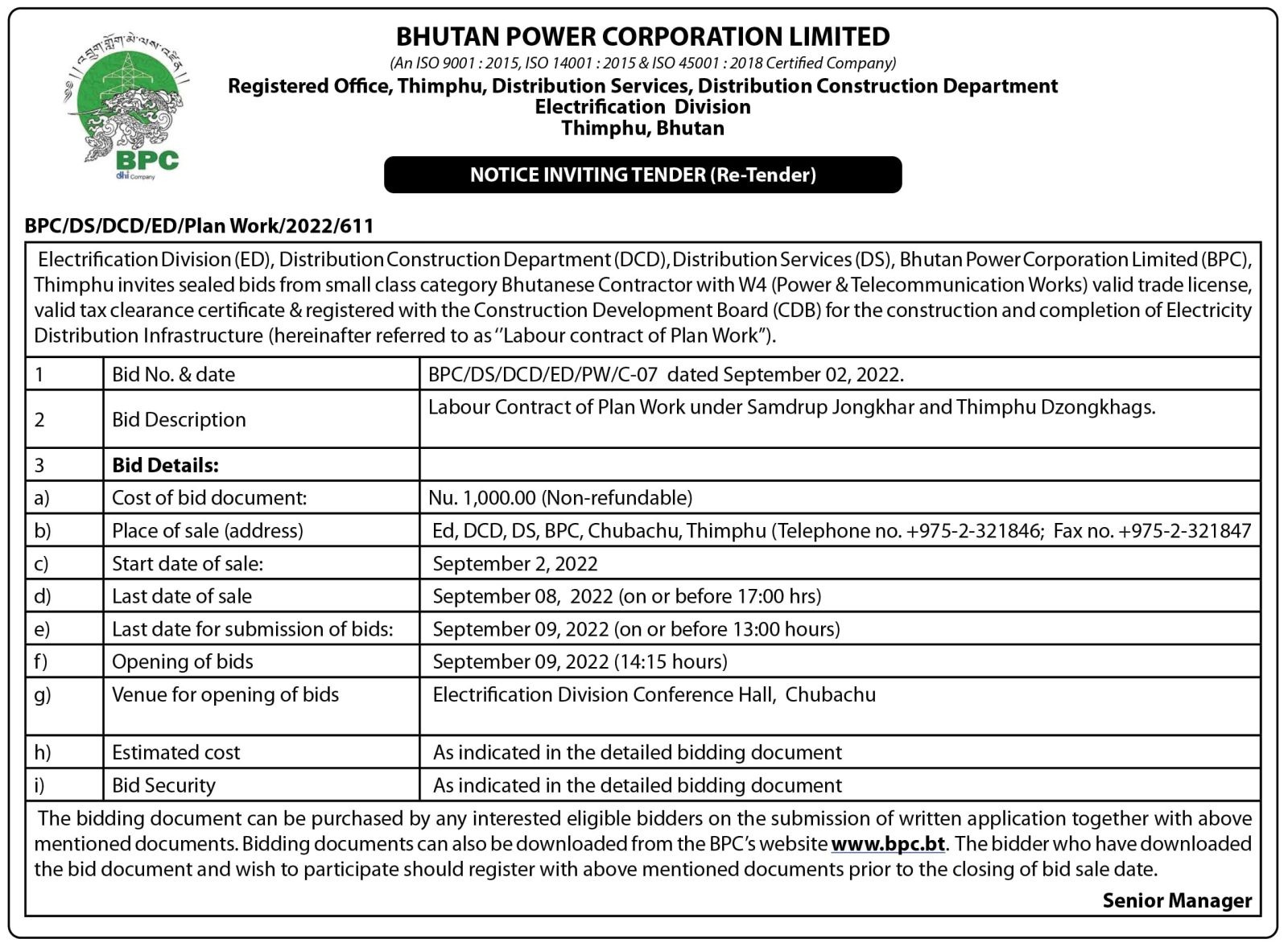

Solar Water Heating Systems (SWH) at CST Mess

A group of final year students has carried out the ‘Design and Installation of (500liter or 7kWh equivalent) Prototype Solar Water Heating (SWH) system at the College Mess as a part of their final year project under their project guide and lecturer in electrical programme, Cheku Dorji.

The SWH system converts diffused solar radiations into heat energy. It has three main components – a solar collector to trap the heat energy from the sun, a hot water storage tank to store hot water and other accessories such as solar pump, pipes, sensors, plumbing accessories and controller.

Presently, the electric cookers used by the college kitchen take around one to two hours to boil water. So a SWH system was designed and installed nearby the kitchen as a part of their final year project to reduce the heating time. The system was designed to produce 500liter of hot water per day to supplement in the mess and the water was to be used to prepare meals for 918 students in the college.

The system is an indirect system whereby a pump is used to circulate hot fluid between solar collector and the hot tank. A solar input energy of 26.1 kWh (generated using the solar collectors, having net area of 10m2) was required to heat 500liter of water.

The system preheated the cold water to the temperature of 50-60 oC before supplying it to electric cookers, whereby it reduced 60 to 70% of the time required by electric cooker to heat the water (currently). This saved significant amount of electrical energy consumption by electric cookers. Furthermore, this could also be used as a prototype for educational purpose and hands on training.

The SWH have both social, economical and environment benefits as the free energy from sun (solar) is used to heat the water which helps to reduce the use of electricity or wood or fuel whereby saving money and making it more economic.

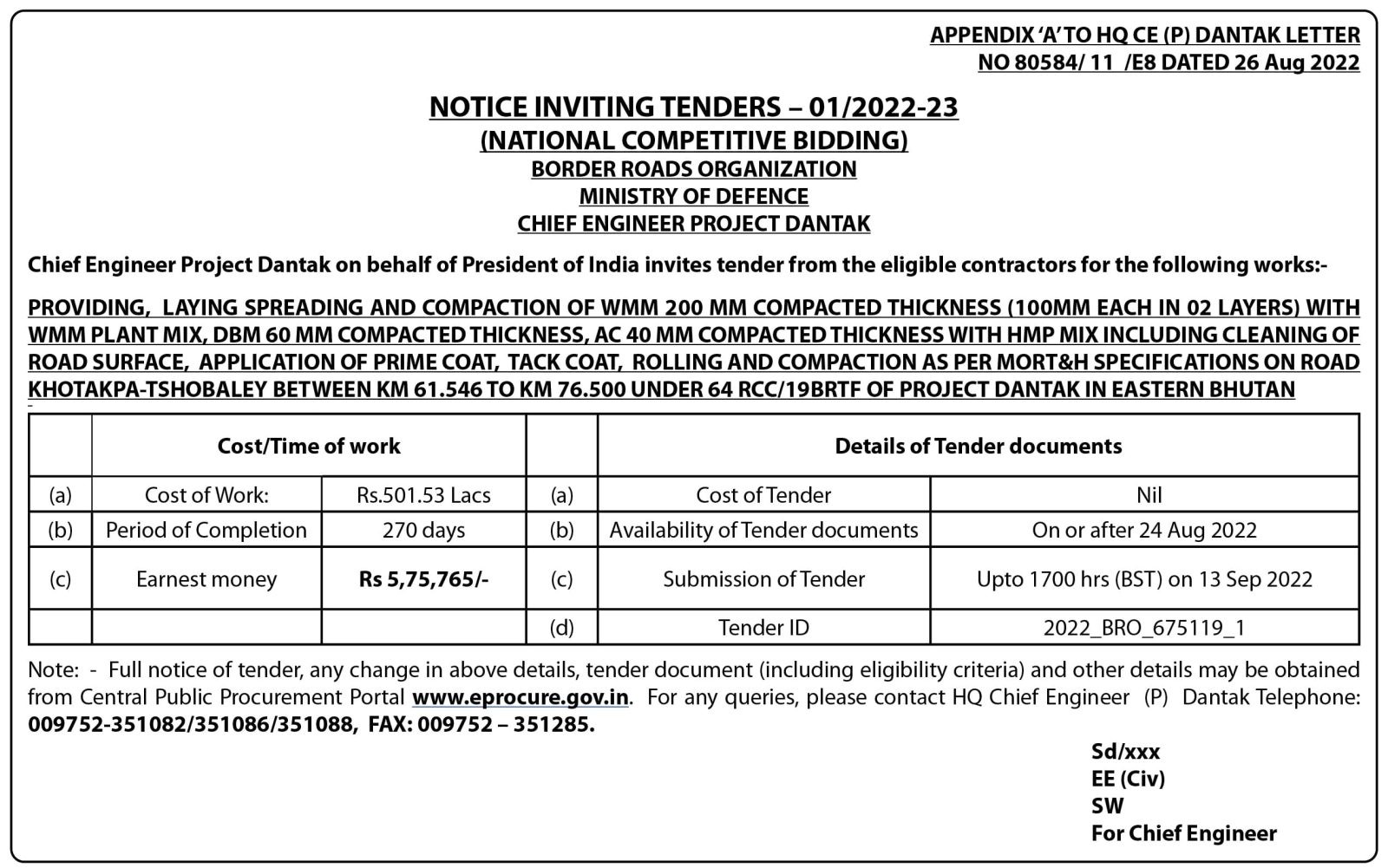

Plastic Paver blocks

A team of civil engineering students has developed paving blocks from plastic waste, which can be used in footpaths. After Phuentsholing Thromde started measures to curb plastic waste in the town, they have initiated the idea to develop paver blocks.

Through the Thromde’s support, five students have developed three different types of paver blocks using sand. The first variety is derived after mixing an equal amount of sand and plastic bitumen without using binding materials. The second type of block contains 60% plastic and 40% sand, and the third contains 70% plastic and 30% sand.

“It can be a lot economical as we can do away with the use of cement, thus cutting the cost,” Karma Tempa, a civil engineering lecturer said.

“The product is ready for use with expected result. The paver blocks have also been tested and withstand temperatures up to 70 Degree Celsius, which is very much convenient to be used in warmer regions,” he said, adding that the blocks will definitely be used in other colder climatic conditions as they have the capacity to expand and contract.

The product can curb plastic waste in the country, according to the team. The team has used soft plastics so far for the project. More than 7kg of plastic is required to mould a block containing 70% of plastic and 6kg block containing 50% and 4kg for 60% of plastic.

“The sample which gives best results on durability will be recommended for future use,” the team says, adding that they, however, don’t have mechanized machine to melt plastic and mould the blocks.

The team currently melts the plastic in a pan manually. They have tried to mechanize the system by fabricating the machine, but it took hours to get the block set after it is molded. “However, the product has great scope in future,” Karma Tempa said.

Meanwhile, the team is planning to work on the mechanisms to release less pollutant in the air. They are aware of the advanced technologies where the pollutants are filtered while burning the plastics and they want to do these tests.

Krishna Ghalley from Thimphu