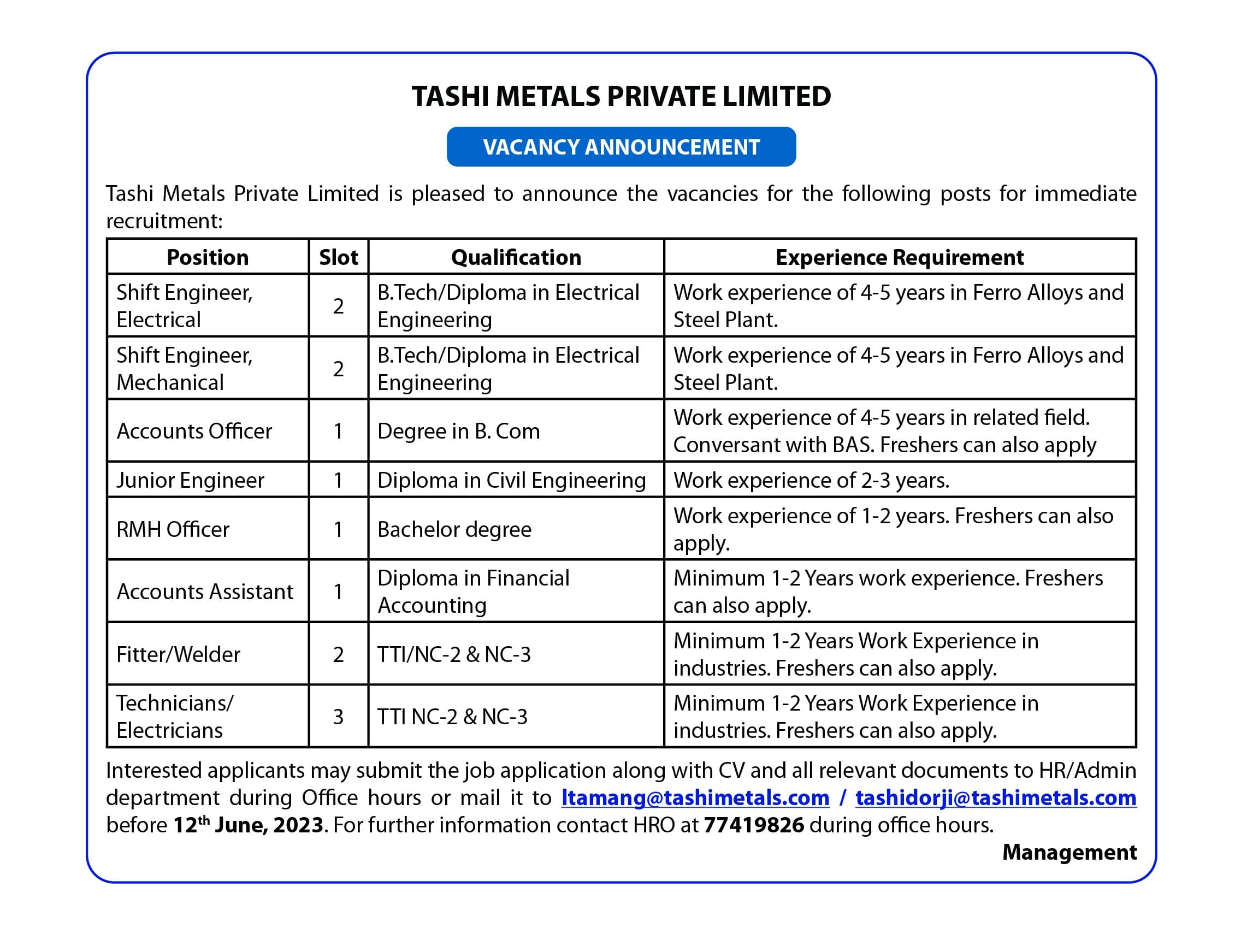

Once an eyesore and a nemesis to residents and passersby with its pungent smell, the sewage tanks have undergone massive changes

The original pond sewerage system in Babesa, Thimphu has undergone a significant transformation over the years.

Established in the early 1990s with an initial capacity of 1.5 million liters per day, the first sewerage pond was constructed openly, without coverage, leading to unpleasant odors impacting people traveling through Babesa Highway and those residing nearby. A decade ago, the smell of human waste which was collected from various areas, including Babesa, Simtokha, Changzamtok, Changbangdro, Thimphu town, and Changgangkha was a huge concern.

Today, the newly implemented sequencing batch reactor (SBR) is now fully covered, effectively controlling foul odors.

“While there is no specific technology to entirely eliminate the odor of faeces, the treatment plant is vastly improved with its full coverage. Although traces of the smell may still be present due to sludge, overall conditions are significantly better than before,” the project manager at Babesa sewage treatment, Kinley Penjor exclaimed.

The new sewerage pond, situated in the same area as the initial one, boasts an increased capacity of approximately 12 million liters per day. “Although the plant is designed for 12 million liters per day, the current intake is 8 million liters per day,” the project manager said, adding that the upgraded sewerage pond was built with funding from the Asian Development Bank (ADB) and cost more than 13 million dollars. The treatment plant is equipped with advanced technology, and the sewerage treatment was done with technology automation.

In the initial cycle of the sewerage plant, raw sewage and some garbage fill the plant. Laborers work diligently during the early hours to separate garbage from raw sewage. To mitigate the unpleasant odor, an odor control system has been introduced, allowing workers to perform their tasks more comfortably. Chlorine powder is also utilized by workers in the treatment plant to neutralize the smell of faeces when dealing with sludge.

The sewerage treatment plant incorporates six processes for sewage waste treatment. First, raw sewage is introduced into the SBR during this phase, facilitating the initial settling of solids within the reactor known as Static Fill. Then, Oxygen is introduced into the SBR during this phase to facilitate bacterial respiration. Bacteria use oxygen to break down organic matter through aerobic processes (Aerated Fill).

The third phase involves the active treatment of sewage, where bacteria break down organic compounds, reducing pollutant concentrations, known as the React phase. After that, treated sewage undergoes settling in this phase, separating solid particles from the liquid, known as Settle.

In the decantation process, the clarified liquid is then separated from the settled solids. The treated water is filtered, and chlorine treatment is applied for disinfection.

During the final and Idle phase, the remaining sewage undergoes further settling, preparing the SBR for the next cycle by removing residual solids.

All these stages occur within a single tank, and advanced technology is employed for sewage treatment compared to previous methods. After treatment, the resulting effluent undergoes further processes to remove pollutants and harmful substances before being released into natural bodies of water, depending on the treatment level achieved.

The upgraded sewage tanks in Babesa, Thimphu, mark a significant leap forward in the community’s sanitation and livability. With the implementation of advanced technology, the sewage treatment plant now operates efficiently, eliminating the unpleasant odors that were once a concern for residents and passersby.

“Thanks to the meticulous efforts of the project team and the use of innovative solutions such as odor control systems, the plant now stands as a testament to improved environmental standards,” the project manager proclaims.

The enhancements not only showcase a commitment to environmental sustainability but also ensure the well-being of the community. Unlike in the past, residents no longer have to contend with offensive smells, and the rigorous treatment processes guarantee that the treated water released into natural bodies is free from health implications. This transformative initiative exemplifies the positive impact that thoughtful infrastructure upgrades can have on both the environment and the quality of life for the people of Babesa.

Tandin Tshewang from Thimphu