Securing raw materials for heavy and medium industries in the country is one of the major challenges that they currently face.

Industries feel that securing raw materials is paramount for their survival. Most of the industries are mineral-based, and except for cement industries, no other industries are secure about their raw materials. Except for electricity other materials are either mineral-based or imported from India.

The industries expressed that a provision for allocating minerals first to meet the domestic demand before exporting should be included during the consultation meeting conducted by economic affairs committee members with the industries on Mines and Minerals Management Bill 2020.

Among 55 registered industries with Association of Bhutanese Industries (ABI), only seven industries have captive mines from where they extract the minerals for industrial use as raw materials. Rest, they either procure from other mines or import from India.

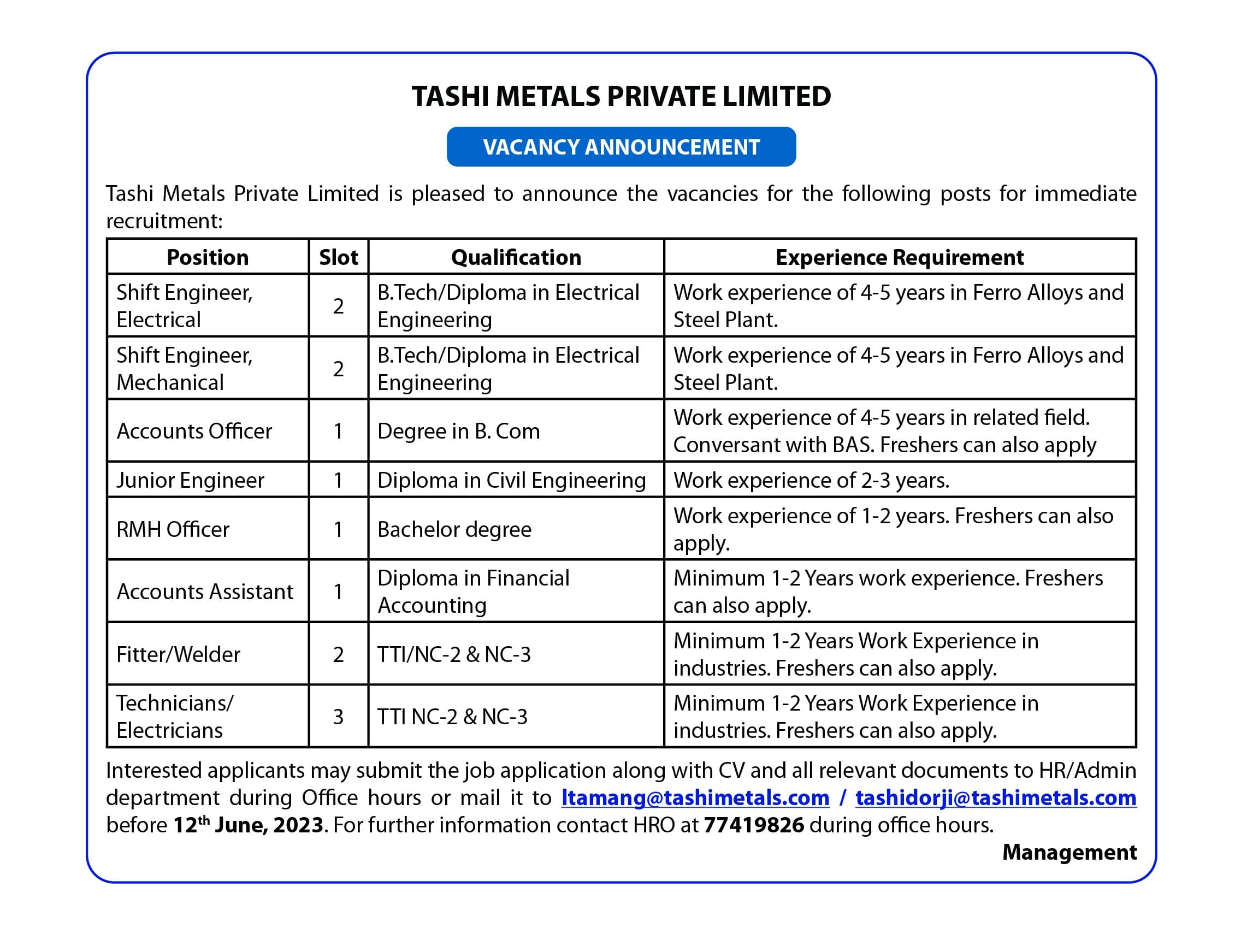

The ferrosilicon industries use Quartz, Quartzite, LAMC (Low Ash Metallurgical Coke), charcoal and coal as their raw materials. Of them only quartzite is available within the country and the rest has to be imported.

For silicon carbide and steel industries, quartz, coke, sponge iron, scrap and pool or pig iron are used and cement industries use limestone, clay, sandstone, slag fines, iron ore, granulated slag, gypsum, coal and fly ash.

Among these raw materials, only limestone, gypsum, clay and sandstones are available within the country. Also, these industries procure LAMC and slag fines from amongst the industries within the country.

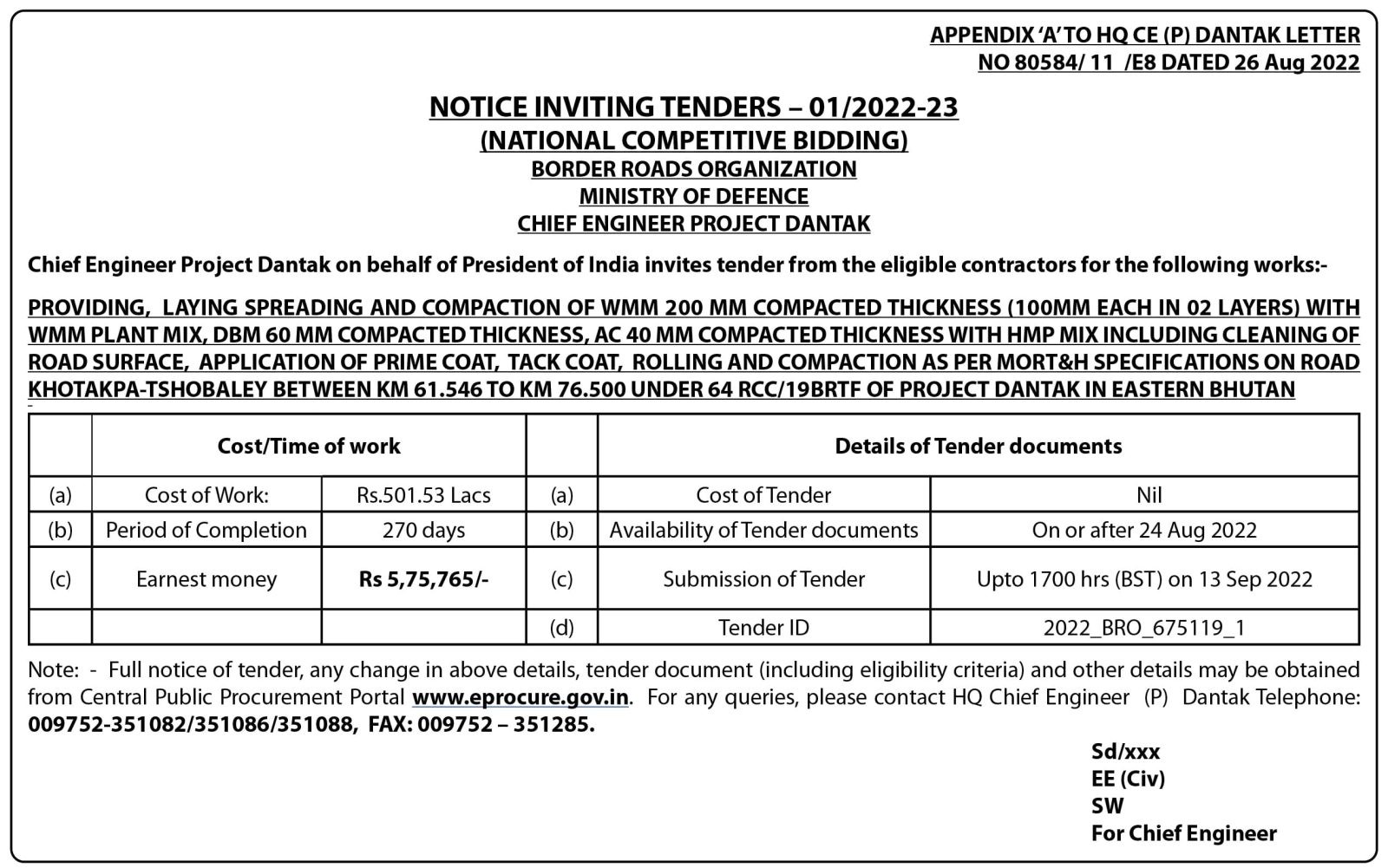

There is only one LAMC producing industry in Pasakha which provides raw materials to the other industries which are currently shut down. Kingyal Coke and Chemicals Pvt Ltd (KCCPL) commissioned in 2013 is the only Semi Coke Manufacturing Plant in the country. The company manufactures and supplies indigenously premium Semi Coke, an essential and primary ingredient for the Ferro Alloys Plants. The Ferro Alloys plants were heavily reliant on imported Coke from India till then. The commissioning of KCCPL provided a convenient and superior “next door” substitute to the import of this critical but mostly erratic and often substandard material from India.

Procuring LAMC from within the country is one of the measures for the industries which curbs the outflow of INR. The company has also contributed in curbing INR outflow through supply of essential materials to the ferro alloys industries which otherwise should be imported from India. Shutting down of KCCPL means that the LAMC and semi coke are now imported from India. While established industries are secured with the captive mines, there are other industries which procure materials from the mining companies.

Krishna Ghalley from Phuentsholing